Mawdsleys Repairs Motors for Latvian Navy

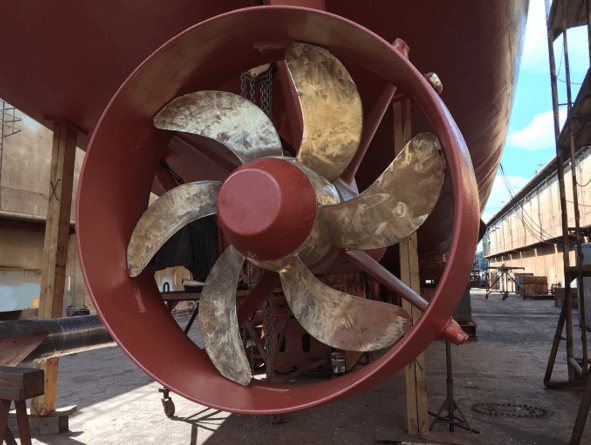

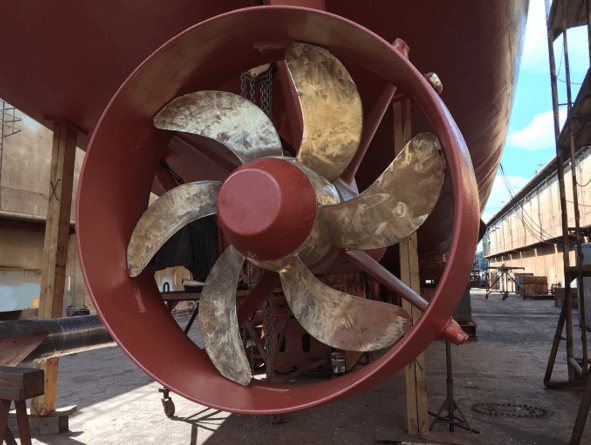

Mawdsleys has gained an increasing number of naval and marine contracts due to its expertise in the repair and refurbishment of specialist equipment such as stern motors. Recently, Mawdsleys took receipt of a job for the repair of motors for the Latvian Navy. The Latvian Navy has a fleet of 18 ships and the Latvian… Read more »