Making up the magnetic field within DC motors and generators, field coils are essential to the proper performance of rotating equipment – a motor will not run in the event of coil failure.

Mawdsleys provides a complete field coil repair service for all makes and models of DC motors and generators, our in-house workshop is also fully equipped to replace existing field coils with new ones should they be beyond repair.

A field coil is an electromagnet used to generate a magnetic field in rotating electrical machinery. Coils are used in pairs which are connected to give north and south poles around the circumference of the frame, these coils are made by winding insulated copper wire or strip around laminated steel cores.

The image above shows a DC motor with 4 main pole coils and 4 interpole coils, the larger main poles provide the magnetic flux and are connected to a field supply, the smaller interpoles then assist with the commutation of the motor and are connected in series with the armature.

Field coil failure or damage will inevitably lead to motor underperformance or failure. Common reasons for field coil failure within DC motors and generators include:

Additionally, some faults may occur with the flexible leads that are used to connect the ends of the coils to each other and into the terminal box. These leads can be replaced if a clean connection can be made onto the coil without damaging the insulation.

In the instance that a field coil cannot be repaired, the motor or generator will need to undergo a rewind; this is essentially replacing the defective coils with new ones.

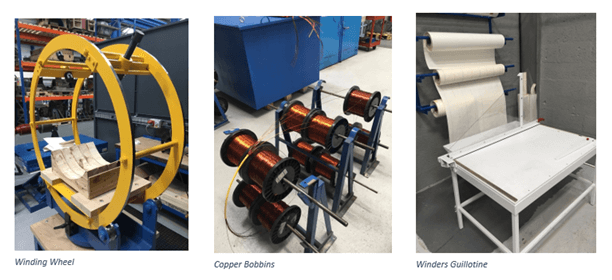

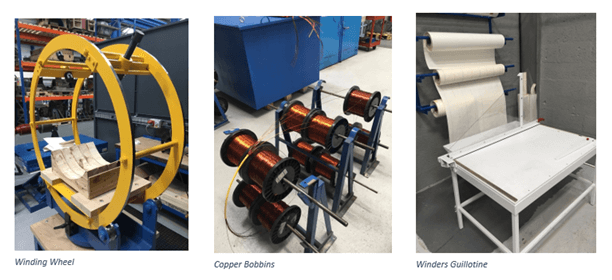

At Mawdsleys, we have a fully equipped state of the art motor winding workshop on site, with a winding department and purpose designed precision jugs enabling us to carry out rewinds to a high standard and with a fast turnaround on service. The rewinding process is as follows:

If your DC motor or generator is experiencing underperformance or complete failure, Mawdsleys can help. We provide a nationwide service to our clients, offering a fast turnaround on service. For more information, call one of our team today on 0117 955 2481.