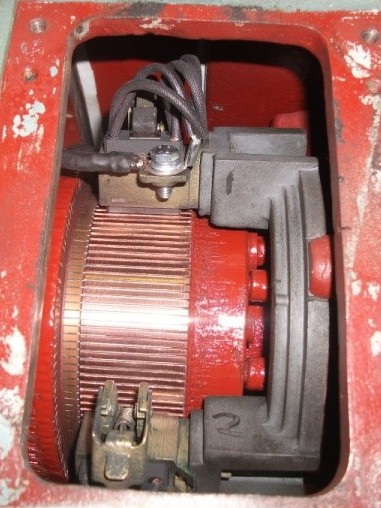

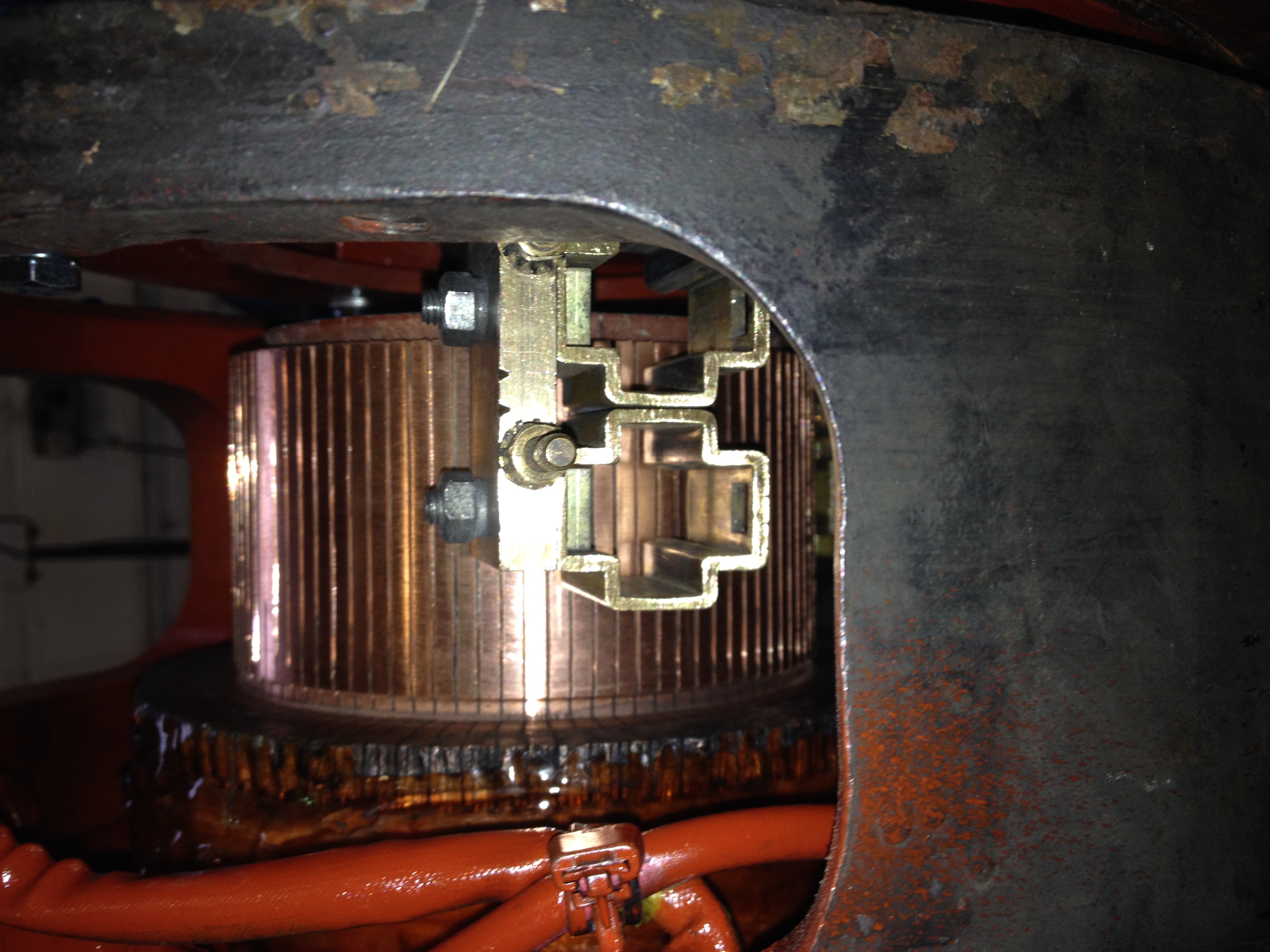

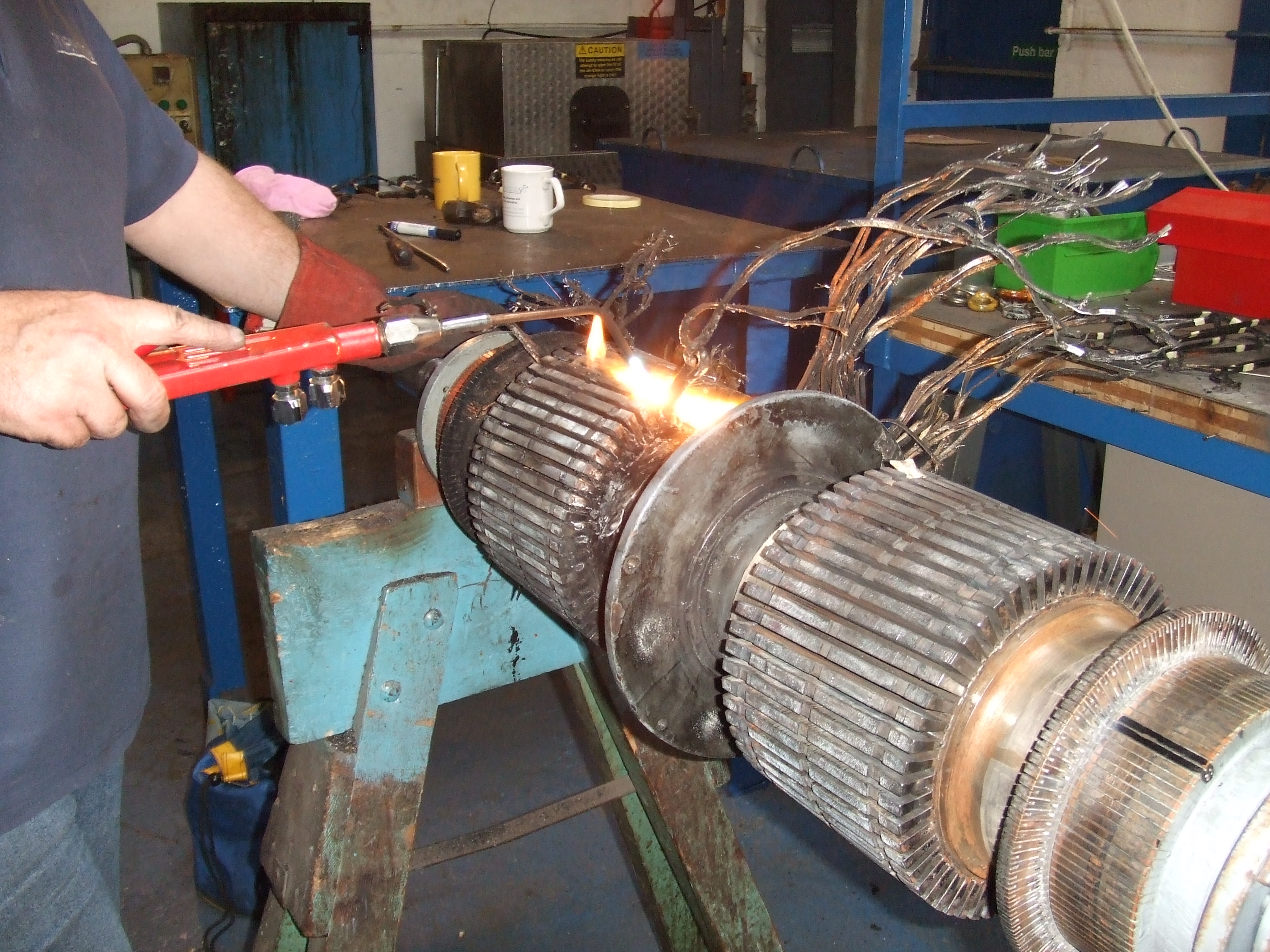

Traction Motor Investigations & Overhauls

Traction motors are machines that convert rotational torque into a linear motion e.g electric vehicles, forklift trucks, elevators, conveyors etc. The motors are heavy duty and able to withstand frequent high torque loads. Our customers regularly send us both AC and DC traction motors for fault investigation, repair or overall. On this occasion an ELMO 5.5kw… Read more »