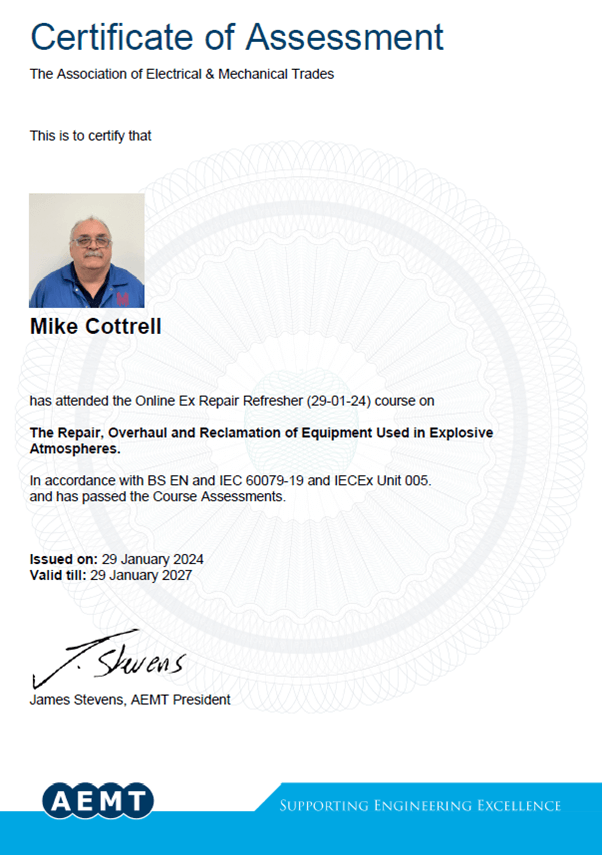

At Mawdsleys we take pride in our commitment to excellence and staff development. We are pleased to announce that two of our engineers have completed certifications in the repair of hazardous area equipment (ATEX motors).

Mike, completed the Online Ex Repair Refresher course, focusing on the repair, overhaul, and reclamation of equipment used in explosive atmospheres. This certification ensures that Michael remains up to date with the latest standards and practices outlined in BS EN and IEC 60079-19 and IECEx Unit 005 as well as reassessing his competency in working with ATEX equipment.

Mark has successfully completed both the Ex Theory and Ex Hands-On courses, giving him the fundamental knowledge and skills to safely work on equipment used in explosive atmospheres, aligning with BS EN and IEC standards.

Find out more about the certifications in our latest blog post.

The Ex Repair Refresher Course completed by Mike is a refresher course for experienced engineers in hazardous area equipment repair, overhaul, and reclamation. The one day course covers the following topics:

The Ex theory course completed by Mark offers comprehensive theoretical training in hazardous area equipment repair, focusing on rotating machinery. The two day course covers the following topics:

Following completion of the theory course, Mark was eligible to take the hands-on course, in order to gain practical expertise. The two day course covers the following topics:

At Mawdsleys, we understand the critical importance of maintaining and repairing ATEX/ex motors to ensure efficiency and safety in potentially explosive atmospheres.

By investing in training programs and empowering our engineers with the latest knowledge and skills, we reinforce our position as a leader in the industry, offering a complete and efficient service for these types of motors.

For more information about our comprehensive ATEX motor services, give one of our team a call today on 0117 955 2481 or fill out a contact form and one of our team will get back to you.